9+ plastic injection molding quality engineering

Plasticizing involves high torque and low rotational speed while injection requires. Shop by department purchase cars fashion apparel collectibles sporting goods cameras baby items and everything else on eBay the worlds online marketplace.

Top 10 Plastic Injection Molding Posts Of 2016 The Rodon Group

Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polarIts properties are similar to polyethylene but it is slightly harder and more heat resistant.

. Join a growing industry leader and embrace the challenge of a fast-paced rapidly evolving medical device industry. This is a quick welding process and can be performed continuously. The word plastic derives from the Greek πλαστικός plastikos meaning capable of being shaped or molded and in turn from πλαστός plastos meaning molded As a noun the word most commonly refers to the solid products of petrochemical-derived manufacturing.

Mold opening is a low-force high-speed movement and mold closing a high-force low-speed movement. Microsoft has responded to a list of concerns regarding its ongoing 68bn attempt to buy Activision Blizzard as raised by the UKs Competition and Markets Authority CMA and come up with an. 1 Add a vent at the last filled place 2 Redesign the gate and runner system.

A homogenous melt is required for consistent part quality but achieving it requires balancing a number of factors including barrel usage and temperature as well as screw speed. We serve a variety of industries including medicalpharma foodbeverage and point of. 2 Shot Injection Molding.

Packaging is the science art and technology of enclosing or protecting products for distribution storage sale and use. A USA-based injection molder providing a complete manufacturing solution and extensive upfront engineering support for your plastic parts. As a result molten plastic takes the injection mold core and cavity shape.

Analyze and report data to identify defect trends within product criteria. Global Automotive and HVAC. After the solidification of molten plastic the finished part is ejected out of the mold.

MBS Advisors Leominster Massachusetts Quality Engineer - New Product Development. Polypropylene PP also known as polypropene is a thermoplastic polymer used in a wide variety of applications. It is also used for forming glass bottles or other hollow shapes.

A plastic welding rod also known as a thermoplastic welding rod is a rod with circular or triangular cross-section used to bind two pieces of plastic together. Providing High-Volume Custom Plastic Injection Molding Solutions Since 1956. 4Volatiles are created from moisture in the plastic degradation of additives or plastic andor air mixed in the melt.

Injection molding machines perform a wide range of mechanical movements with differing characteristics. The volatiles come between the mold surface and the plastic melt preventing the melt from picking up the texture. Ascent Solar Technologies Inc.

Microsoft is quietly building a mobile Xbox store that will rely on Activision and King games. It contains the chemical elements carbon and hydrogen. Different plastic resins impart different end-use properties such as tensile strength and impact resistance.

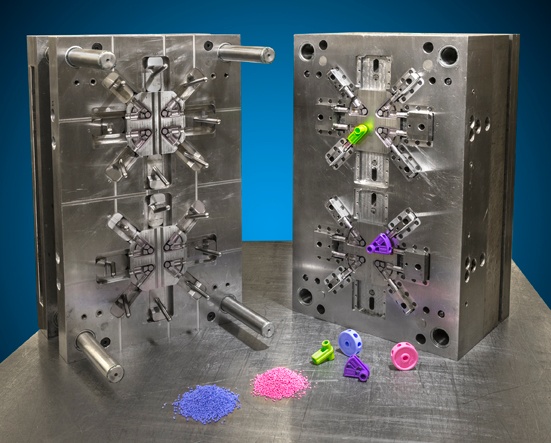

Injection Molding is a widely used plastic manufacturing process to manufacture plastic parts in large volumes and at low cost. Extrusion blow molding injection blow. Packaging can be described as a coordinated system of preparing goods for transport warehousing logistics sale and end usePackaging contains protects preserves.

Quality Engineer - Plastic Injection Molding. Seeking Quality Engineer that strives to adopt a Zero-Defect attitude in plastics manufacturing. Using design software and over 125 presses automated machines in our state-of-the-art robotics facility.

We suggest you read this article on injection molding. Firstly molten thermoplastic with high pressure injects into an injection mold during injection molding. It is produced via chain-growth polymerization from the monomer propylene.

In injection molding material is fed through a hopper into an extruder where a reciprocating screw mixes and melts the material then injects it into a mold. The materials properties are determined by short-range van der Waals attractions between polymers chains. Reduce thickness inconsistency and try to ensure uniform wall thickness Mold design.

Bachelors degree in Engineering Quality Managementrelated field or 2 years Quality leadership experience. This is a common defect that shows up as shiny streaks on the part and is caused by the presence of volatiles in the melt Fig. Blow molding or moulding is a manufacturing process for forming hollow plastic parts.

We are an employee-owned quality injection molding company with experience capabilities and state-of-the-art facilities that allow us to handle simple to complex operations throughout all stages of. Were Midwest Mold your ideal partner in plastic part developmentWe build production and pre-production plastic injection tooling and injection molded parts for low volume pre-production and research and development. 1 Reduce the injection speed.

Metal to Plastic Conversion. Clive Maier Teresa Calafut in Polypropylene 1998. The polymer is usually an epoxy vinyl ester.

Microsofts Activision Blizzard deal is key to the companys mobile gaming efforts. This article covers various plastic part design guidelines for injection molding that you can implement in your part design to ensure good quality parts. Quality Assurance LEARN MORE.

Quality Engineer Plastic Injection Molding. Two sheets of plastic are heated via a hot gas or a heating element and then rolled together. It is best to engage with a supplier that can provide a set of.

Plastic part design guidelines for injection molding ensure good quality manufactured parts. Packaging also refers to the process of designing evaluating and producing packages. Most hotcold equipment manufacturers provide application engineering support which should be consulted within the project-definition and the implementation phase.

IATF 169492016 ISO 140012015 and ISO 90012015. In chemical terms polystyrene is a long chain hydrocarbon wherein alternating carbon centers are attached to phenyl groups a derivative of benzenePolystyrenes chemical formula is C 8 H 8 n. Also called fibre-reinforced polymer or in American English fiber is a composite material made of a polymer matrix reinforced with fibresThe fibres are usually glass in fibreglass carbon in carbon-fibre-reinforced polymer aramid or basaltRarely other fibres such as paper wood or asbestos have been used.

We are designers engineers and manufacturers who are passionate about what we do we take ideas and make them into physical working. We manufacture injection molded components with quality and precision. In general there are three main types of blow molding.

There are hundreds of plastic materials for injection molding. Injection molded plastics also have specific processing requirements such as melt temperature and molding pressure. Solid understanding of the following bodies of knowledge.

It is caused by the air being unable to escape from the parting surface the ram or the vent when the two melt fronts meet. Housing more than 100 machines within our 9 global locations we are able to offer. In conventional injection molding molten polymer enters the mold cavity and contacts the cooler cavity surface.

Injection molding is a manufacturing process for producing parts by injecting molten material into a mould or moldInjection moulding can be performed with a host of materials mainly including metals for which the process is called die-casting glasses elastomers confections and most commonly thermoplastic and thermosetting polymers. The noun plasticity refers specifically here to the deformability of the materials used in the.

Quality Engineering Manager Job Description Velvet Jobs

China Plastic Injection Molding Process And Plastic Injection Molding Service Companies China Plastic Injection Molding Companies With Tooling And Injection Moulding Die Makers

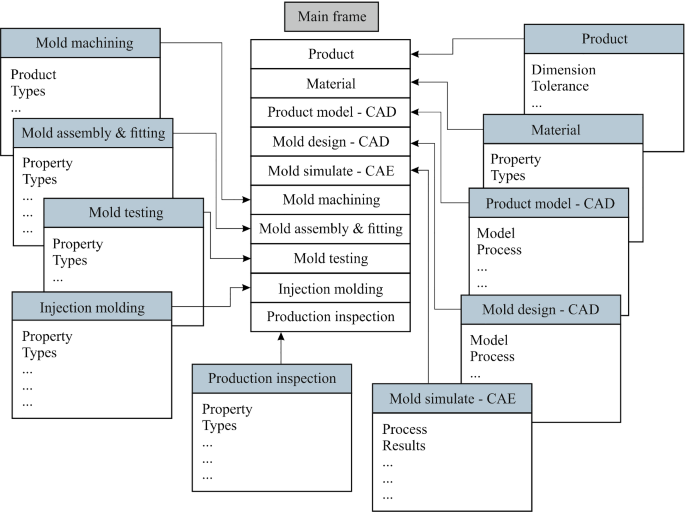

Injection Mold Manufacturing Quality Control Assurance Upmold

Nvs54s5jh Ammm

Plastic Injection Molding Quality Management System Matrix Tool

Advanced Materials Guide For Injection Molding Fictiv

Pdf Reducing The Sink Marks Of A Crystalline Polymer Using External Gas Assisted Injection Molding

Plastic Injection Molding In China

Hi Tech Plastics Engineering Offers High Quality Moulds For Plastic Injection Moulding Machine Blow Moulding Machine Extrusion Blow Moulding Machine By Hitech Plastics Engineering Facebook

Tooling 4 0 Connecting Industry 4 0 Technology To Your Molds And Molding Process Moldmaking Technology

Staff Supplier Quality Engineer Resume Samples Velvet Jobs

Injection Molding Machinery Solution Plastics Molding Machinery

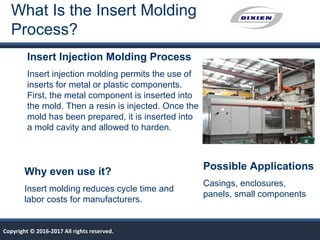

What Is Insert Molding

The Plastic Injection Molding Process Videos Information For Importers

Pdf Continuous Improvement Of Injection Moulding Using Six Sigma Case Study

High Quality Engineering Plastics Injection Molding Products China Molding Parts Injection Molding Parts Made In China Com

Plastic Injection Molding Design For Manufacture Improvements Sofeast